Particulate Filtration using Multifunctional Metallic Nanowire Foams

Posted in News Story

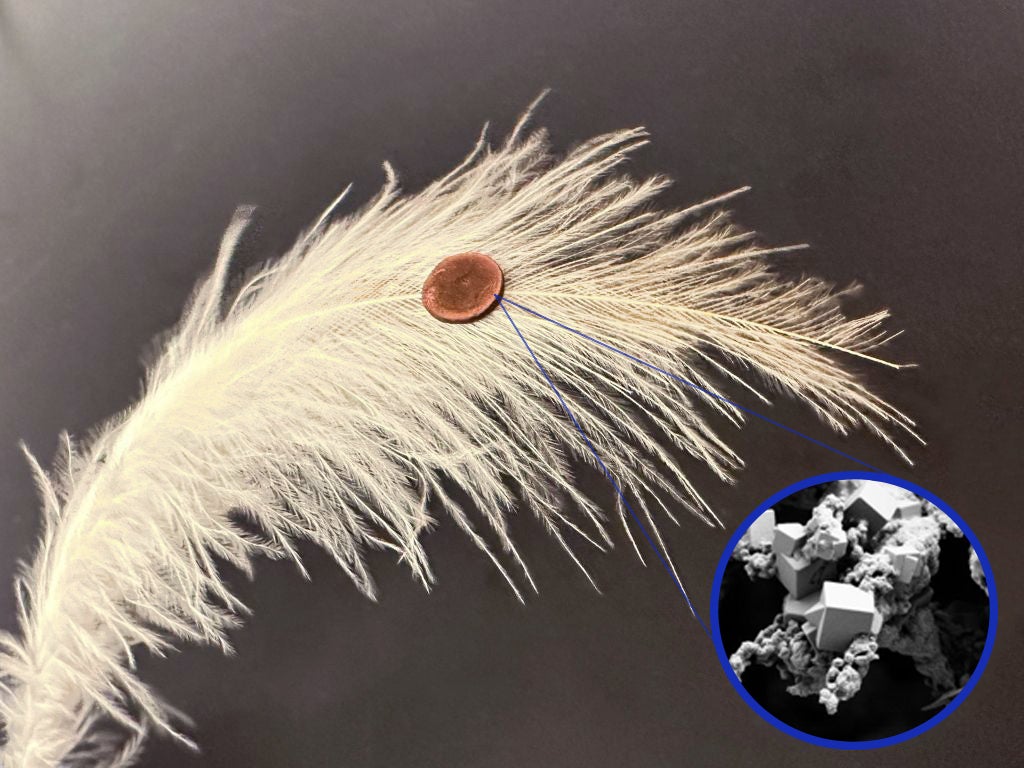

In a study led by James Malloy in Prof. Kai Liu’s group, a multifunctional filtration platform is demonstrated using porous metallic nanowire foams that are efficient, robust, antimicrobial, and reusable, with the potential to guard against multiple hazards. The complex 3D foam microstructures are also investigated, and their correlation with the filtration performance is revealed. These results are recently published in the journal Nanoscale.

Ultrasmall “lung-penetrating” airborne particulates pose potentially severe health risks due to their ability to penetrate deep into the respiratory system, from the transmission of infections such as COVID-19 to air pollution. One of the most effective methods of combating the spread of COVID-19 has been the use of high-efficiency face masks to prevent the inhalation of viral particles attached to ultrasmall aerosols and droplets. The gold standard N95 masks are indeed highly efficient, but cannot be easily cleaned, reused or recycled, due to the reliance on electrostatics and polymer fibers.

Liu’s group has previously demonstrated that nanowire-based low-density metal foams are highly efficient, robust, and breathable against deep submicron particulates. The copper foams can also be easily cleaned and decontaminated to allow sustained use, and eventually recycled at the end of their useful lifetime. The group has been selected as a Phase 1 Winner and a Phase 2 Finalist of the 2021-2022 BARDA/NIOSH Mask Innovation Challenge.

Despite the promising initial results on such nanoporous metallic foams, a quantitative understanding of how the synthesis conditions and foam microstructures affect the filtration performance was still lacking.

In this study, James Malloy, Erin Marlowe, and Christopher Jensen in Liu’s group have elevated these copper foams into a multifunctional filtration platform. The foams are not only effective against “lung-penetrating” particulates, but also are antimicrobial and reusable. They could be integrated with additional features to guard against multiple hazards. The team has also investigated the foam microstructures, detailing how the growth parameters influence the overall surface area and characteristic feature size, as well as the effects of the microstructures on the filtration performance.

A high school intern, Isaac Liu, worked under Prof. Gen Yin’s guidance and carried out imaging analysis to quantitatively understand the 3D foam microstructures from 2D scanning electron microscopy (SEM) images. Another undergraduate student in the Georgetown NSF-REU program in the Physics department, Thomas Hulse, also contributed to the foam synthesis.

The team found that nanogranules deposited on the nanowires during electrodeposition greatly increase the surface area. Interestingly, while foam surface areas are generally important for filtration efficiency, once they are sufficiently high, the sizes of the foam surface features play a more prominent role.

The copper foams are also antimicrobial, which is advantageous in disabling trapped viruses and bacteria. Antimicrobial tests performed by Drs. Anne F. Murray, Daniel Bryan, Thomas G. Denes, and Dustin A. Gilbert at the University of Tennessee on the foams show a >99.9995% inactivation efficiency after contacting the foams for 30 seconds.

These results demonstrate promising directions to achieve a highly efficient multifunctional filtration platform with optimized microstructures.

This work has been supported in part by the Georgetown Earth Commons Impact Awards, Office of Technology Commercialization (OTC) Gap Funds, the McDevitt bequest, and the NSF-REU program (DMR-1950502).